No products in the cart.

News

The World’s First Anti-Coronavirus Surgical Mask by Wakamono, Vietnam

In December 2019, a novel coronavirus (SARS-CoV-2) was first detected in Wuhan, in China’s Hubei province. On 11 March 2020, the World Health Organization (WHO) acknowledged and characterized the condition as a pandemic owing to the rapid spread of the virus across the globe infecting millions of individuals. Scientists are fighting tirelessly to find out ways to curb the spread of the virus and eradicate it.

SARS-CoV-2 is regarded as highly contagious and spreads rapidly through person-to-person contact. When an infected person sneezes or coughs, their respiratory droplets can easily infect a healthy individual. Besides enforcing social distancing, common citizens are encouraged to wear face masks to prevent droplets from getting through the air and infecting others.

Despite the efficiency of N95, a respiratory protective device, to filter out 95% of particles (≥0.3 μm), surgical facemasks are single-use, expensive, and often ill-fitting, which significantly reduces their effectiveness. Nanoscience researchers have envisioned a new respirator facemask that would be highly efficient, recyclable, customizable, reusable, and have antimicrobial and antiviral properties.

Nanotechnology in the Production of Surgical Masks

Nanoparticles are extensively used for their novel properties in various fields of science and technology.

In the current pandemic situation, scientists have adopted this technology to produce the most efficient masks. Researchers have used a novel electrospinning technology in the production of nanofiber membranes. These nanofiber membranes are designed to have various regulating properties such as fiber diameter, porosity ratio, and many other microstructural factors that could be utilized to produce high-quality face masks. Researchers in Egypt have developed face masks using nanotechnology with the help of the following components:

Polylactic acid

This transparent polymeric material is derived from starch and carbohydrate. It has high elasticity and is biodegradable. Researchers found that electrospun polylactic acid membranes possess high prospects for the production of filters efficient in the isolation of environmental pollutants, such as atmospheric aerosol and submicron particulates dispersed in the air.

Despite its various biomedical applications (implant prostheses, catheters, tissue scaffolds, etc.), these polylactic membranes are brittle. Therefore, applying frequent pressure during their usage could produce cracks that would make them permeable to viral particles. However, this mechanical drawback can be fixed using other supportive nanoparticles that could impart mechanical strength, antimicrobial and antiviral properties, which are important in making face masks effective in the current pandemic situation.

Copper oxide nanoparticles

These nanoparticles have many biomedical applications, for example, infection control, as they can inhibit the growth of microorganisms (fungi, bacteria) and viruses. It has also been reported that SARS-CoV-2 has lower stability on the metallic copper surface than other materials, such as plastic or stainless steel. Therefore, the integration of copper oxide nanoparticles in a nanofibrous polymeric filtration system would significantly prevent microbial adherence onto the membrane.

Graphene oxide nanoparticles

These nanoparticles possess exceptional properties, such as high toughness, superior electrical conductivity, biocompatibility, and antiviral and antibacterial activity. Such nanoparticles could be utilized in the production of masks.

Cellulose acetate

This is a semi-synthetic polymer derived from cellulose. It is used in ultrafiltration because of its biocompatibility, high selectivity, and low cost. It is also used in protective clothing, tissue engineering, and nanocomposite applications.

With the help of the aforesaid components, researchers in Egypt have designed a novel respirator filter mask against SARS-CoV-2. This mask is based on a disposable filter piece composed of the unwoven nanofibers comprising multilayers of a) copper oxide nanoparticles, graphene oxide nanoparticles, and polylactic acid, or b) copper oxide nanoparticles, graphene oxide nanoparticles, and cellulose acetate, with the help of electrospun technology and high-power ultrasonication. These facemasks are reusable, i.e., washable in water and could be sterilized using an ultraviolet lamp (λ = 250 nm).

The World’s First Anti-Coronavirus Surgical Masks by Wakamono

Wakamono is a Nano Biotechnology company that was established in 2010 in Vietnam. They have been successful in the production of the world’s first anti coronavirus surgical mask. This surgical face mask has shown its effectiveness against 99% of SAR-CoV-2 strains.

Wakamono surgical masks are also effective against influenza A H1N1 (enveloped viruses), poliovirus-I (non-enveloped viruses), and 99% of harmful bacterial pathogens.

The mask’s efficiency was tested and certified by reputable and reliable independent laboratories following the standard ISO 18184:2019. Additionally, Wakamono surgical masks could successfully meet and exceed the US’s highest FDA standards, i.e., ASTM F2100 level 3 and European CE EN 14683 Type IIR.

Importance and Development of Wakamona Surgical Masks

An N95 medical respirator can filter out 95% of a particle of approximately 0.3-micron size, as stated above. However, the novel coronavirus is approximately 0.05 – 0.2 micron. It is always advised that users should not touch the mask surfaces to avoid contamination on either side. The filtered pathogenic microorganisms adhered to or trapped on the mask’s surface do not die but continue their life cycle. For example, coronavirus lives for up to seven days on disposable masks.

While addressing these problems, the scientists at Wakamono developed the surgical mask with dual properties, i.e., filtration of harmful pathogens and destruction of trapped viruses and bacteria.

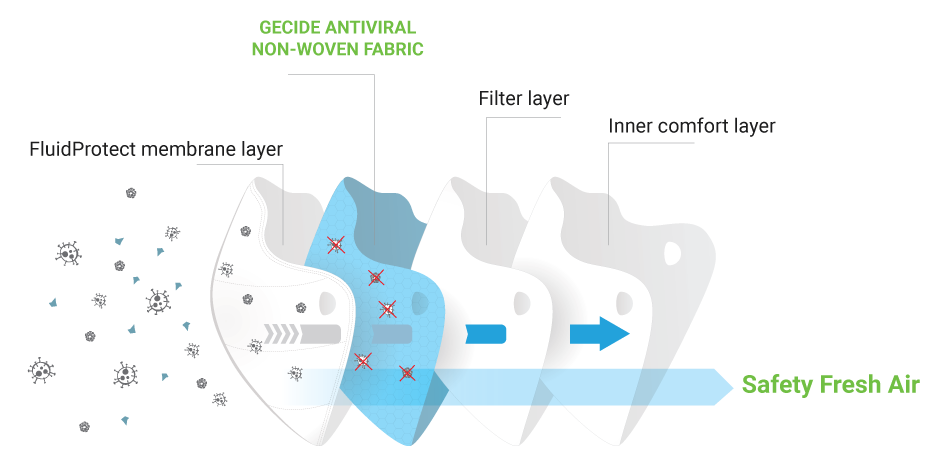

In the production of the multilayered surgical mask, Wakamono has utilized Gecide fabric. These fabrics provide antibacterial property against harmful bacterial pathogens. The inner layer of the mask comprises Gecide fabric layer. This inner layer is covered with millions of organic nanoparticles. These nanoparticles can form traps to weaken and destroy harmful pathogens (virus and bacteria). All the biocide organic and natural components used in the development of the surgical masks are safe in accordance with the in vitro cytotoxicity ANSI/AAMI/ISO 10993-5:2009 by Pacific Labs (USA). Wakamono masks do not utilize any metal nanoparticles in the masks.

The use of Wakamono surgical masks could significantly decrease the infection rate as it would effectively reduce virus transmission. Therefore, this development can act as a potential tool to combat the COVID-19 pandemic.

Source: www.azonano.com